As an ISO certified company, we have an obligation to investigate any of our product failures, but over the years we have been asked more and more to get involved in general failure analysis. We undertake to make an un-biased investigation into any failure involving cable joints and terminations regardless of who manufactured the product.

An 11kV transition joint failed shortly after commissioning at a refurbished Irish factory. The joint was cut out and forwarded to us for inspection.

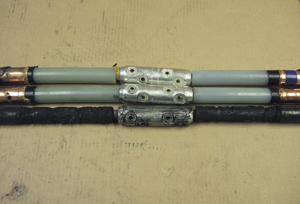

There was a massive amount of damage as a result of the failure. The heatshrink outer sleeve was severely damaged and the armour cage partly melted. Removing these exposed the 3 cores, one of which was completely destroyed.

The other two cores, though superficially affected by the blast, were electrically sound. Breaking down the two remaining cores showed the installer to have removed the screen correctly, jointed the cores and installed all stress grading material and tubing according to the JI provided.

For the amount of damage caused and only to one phase, we were at a loss to find a cause other than mechanical.

After receiving further information from site along with a picture, it appears ropes were attached over the armour removal area and the entire joint and cable winched into a new position. This had buckled the armour cage, and forced one core into the sharp edge of the twisted cage piercing the core insulation tubes.

Questions were also asked about the protection in place for there to have been this level of damage.

The exposed cores, one of which is completely destroyed

An 11kV 3 core transition joint which was audibly discharging.

View Case StudyJoint failure on an 11kV trifurcating transition joint

View Case StudyAn 11kV transition joint failed due to buckled armour cage

View Case StudyProblems with the earth continuity of a low voltage feeder

View Case StudyA cable box reported as "buzzing"

View Case Study